Solid particle contamination is the biggest cause of failure in hydraulic circuits and with lubricating oil.

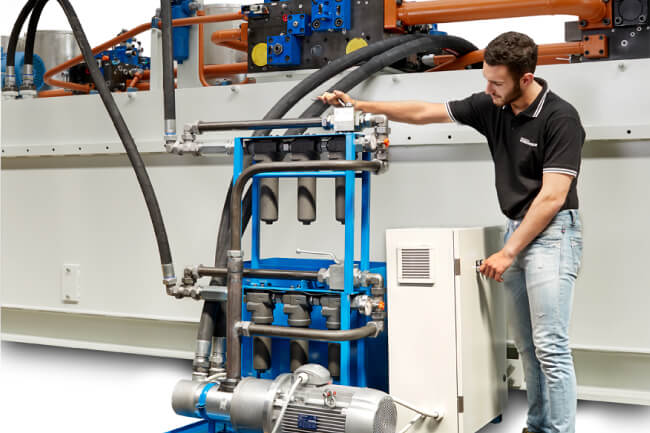

The flushing eliminates contamination in the circuits with the same oil high-speed pumping in the system. The turbulent flow, combined with the high speed induced in the circuit, takes the contaminated particles and transports them to the flow unit filtering system.